SPIRIT 2012 stands for

S - SustainableP - Performance

I - Innovatively

R - Relentlessly

I - Integrity

T - Trust

|

FOREWORD Welcome to Ion Exchange (India) Ltd. and to a career with us that we are sure you will find satisfying and rewarding, offering you exciting opportunities for growth and learning. This manual is an introduction to your Company and we hope it will help you understand our corporate ethos and familiarise yourself with the company, our activities and policies. For easy reading, the manual is divided into two sections: Section A.1 – Meet Your Company Section A. 2 – Our Professional Approach Should you have any questions, Corporate Communications or Human Resource Development Departments will be pleased to assist you and to put you in touch with those departments who can provide details on specific matters. We would also welcome your suggestions on how this manual can meet your needs better. |

A.1. MEET YOUR COMPANY

To be the leader in our business

which is so vital

to people's lives and the environment

The importance of protecting the environment has never been greater than now. The capacity of the earth, our spaceship, to absorb more waste or more energy is fast getting exhausted. Environmental damage has already caused the extinction of hundreds of species of plants and animals. Human beings themselves now face extinction. There is an urgent need to protect the water we drink and use, the air we breathe and the soil on which our plants and crops grow.

Industry faces the challenge of proving that a clean environment and economic wellbeing are mutually compatible; adding value while reducing the use of resources and energy. Sustainable development requires new approaches in the use of technology and is much more than mere growth. Uncontrolled growth in fact is a form of cancer. The world needs a change in quality to enable society to provide human satisfaction by environmentally sustainable means.

Ion Exchange India's (IEI) vision arises from this global and environmental overview. Our core business relates to water and environment management. Water is an increasingly scarce and precious resource, and essential for all human activity and for life itself. We treat water to meet the requirements of society - for use in homes, by communities, by industry, in agriculture… We provide total solutions that purify water, conserve it by recycle, recover valuable products for reuse, minimise the discharge of pollutants into our seas, rivers and lakes and reduce the load on the regenerative capacity of the environment. We do this at optimum cost using minimum energy, with an innovative and integrated approach to technology. We offer solutions too for air pollution control, solid waste management and recovery of energy from waste. We are very fortunate - privileged, indeed, that our business is of such beneficial service to society and the environment.

Business leadership stems from customer satisfaction and service excellence; these must always be our prime concerns. Customer satisfaction is best assured by relating benefits from our service to improvements of his returns on investment; by seeking to first understand needs and then meet them with value added solutions. If our focus is always the customer, leadership and progress are assured.

Our business of total environment management has provided the platform for extending our business lines into urban and rural infrastructure development for drinking water and sanitation, and into organic horticulture which are in line with our vision. They improve the lives of people and the environment, and provide the opportunity for our people to grow. The development of the rural market for all our businesses will be equally challenging and even more satisfying because we shall then be really improving the environment for all in the country. Together, let us make our organisation a shining example of socially responsible business, improving people's lives and the environment.

Our vision will provide a satisfying goal to all who work for the company, enabling us, through our work, to provide comfort and security for ourselves and return to society what we owe to it, with value added.

To satisfy our customers.

To provide the best value for money using innovative and integrated technology.

To serve society by helping to create a clean environment.

To strive for the well-being of our stakeholders.

To pursue the path of continuous improvement.

We work for the satisfaction of our customers, our shareholders, our employees and for the benefit of society of which we are a part.

We would not be in business but for our customers. That is why it is so important that we try to satisfy them, meeting their needs with quality products and service excellence, using technology in an integrated manner to provide optimum solutions and the best value for money.

We owe much to our shareholders who contribute towards the capital required by our company for our assets and working funds.

Our employees are special because it is only their dedicated work which can make the company succeed. So we try hard to develop a friendly work atmosphere and provide as many amenities as we can afford. To provide opportunity for career growth, to pay increasing attention to training and development, to help people undertake more responsibilities, more productive, fulfilling and better paid work. Dealers and vendors are our company's extended family. We must treat them with the fairness and consideration they deserve, as partners in progress, whose prosperity is interlinked with ours.

Any business company has an inherent obligation and responsibility towards society of which it is a part. We are fortunate that our business is, by its very nature, so essential to society that it gives us the opportunity to use technology to improve the quality of people's lives and the environment.

The globalisation of business demands excellence in all we do, in every aspect of our functioning. Each individual, each department, each division and company must become a centre of excellence, constantly challenging earlier performance, competing against international standards to become the best.

The changes taking place in the outside world are opening up wider vistas in water and environment management, providing ample opportunity for sustained growth. To lead in our business requires us to work together, focusing on our mission with the zeal of missionaries, sharing a common vision.

Giving our customers the best value for money.

Helping to protect the environment through conservation and recycling of non-renewable resources.

Establishing policies and systems to achieve organisational objectives through teamwork and individual initiative.

Pursuing excellence through continuous research and development and employee training.

Work ethics that are inspired by professionalism and integrity.

A safe and congenial work environment, respect for our employees and concern for their welfare.

Contributing to the wellbeing of the community.

In 2008, the company's goals for 2012, and the measures, values, efforts and conduct needed to achieve these goals, were encapsulated in SPIRIT 2012

SPIRIT 2012 stands for S - SustainableP - Performance I - Innovatively R - Relentlessly I - Integrity T - Trust |

|

Sustainable

|

Performance

|

Innovatively

|

Relentlessly

|

Integrity

|

Trust

|

2012 Milestone Goals |

|

|

|

Our company firmly believes that its vision of being a market leader in its businesses can be achieved only if it has the trust and association of its employees, customers and investors, whom the company values very highly. The code of conduct has been drafted to ensure that the employees act in accordance with these principles. In respect of matters for which there is no specific rule, employees will have to take an honest, pragmatic approach without compromising the values and principles of the company.

Applicability

The code is applicable to

officers, employees and workers at all levels of the company, whether working

in India or abroad.

Secrecy

The company values honest

dealing with all its customers, dealers and vendors. At all times, whether during

employment with the company or after leaving the company, employees will have

to observe secrecy regarding the affairs of the company and shall keep confidential

all information or knowledge obtained about the company's affairs, its manufacturing

processes and inventions.

Any improvement in processes or products or any new inventions that is made

by an employee shall be the exclusive property of the company and the employee

shall do all things necessary to vest the ownership rights thereof in the company.

Protection of Company's

Property

Employees must use the company's

property with care and should not use it for personal purposes. They should

return to the company at the time of resigning, the items used in the course

of their employment with the company.

Conflict of Interest

Employees should not allow

personal interests and prejudices come in the way of decisions, for e.g., profiting

from confidential information, influencing a business transaction with an entity

with which the company is dealing with. They should always ensure that decisions

taken by them are not detrimental to the interests of the company. The company's

interest should be uppermost in their mind and dealings contrary to this should

be disclosed to their immediate superior or to the management or in-house legal

counsel for appropriate action.

Fair Treatment

of Employees

Employees shall treat each

other with respect and there should be no discrimination with respect to religion,

race, creed, gender, disability etc.

Harassment in Workplace

The company cannot function

and meet its objectives without the support, co-operation and trust of its employees.

The Company has always worked towards the well-being and growth of its employees

and believes in transparent and cordial relations. Employees should not tolerate

harassment of any nature and must report to their immediate superior or management,

any such problem faced by them. The management will maintain confidentiality

and shall extend all co-operation to the employee.

Safety & Environment

Protection

The company is committed

to providing and maintaining a safe and healthy work environment, by establishing

safe operating procedures and practices that protect employees from ill health

and injury.

The company's businesses are undertaken in an environmentally responsible

manner and it is committed to conservation of resources and continual improvement

of processes and activities in order to minimise impact on environment, prevent

pollution and protect the environment.

Customers

Customer satisfaction is

a core value and the company is committed to providing customers the best value

for money through quality solutions and services that meet needs of consumers.

We are focussed on understanding customer needs and obtaining customer feedback

for improving products and services and finding innovative solutions that will

improve the quality of people's lives and the environment.

Shareholders

Our company believes in and

has consistently practised good corporate governance. It provides timely and

accurate information to the shareholders regarding the company's activities

and financials and continuously works towards enhancing shareholder value.

Insider Trading

Inside information means

any information known to an employee which is not yet made public and which,

if made public, will result in manipulation of stock prices. For e.g., financial

results, any major expansion plans or execution of new projects, plans of merger,

amalgamation or takeover etc. is inside information. Employees possessing such

information should not misuse and gain from such information.

Compliance with

Competition Laws

The employees must comply

with competition laws and should not indulge in activities that are in violation

of such laws. The employees shall consult the in-house legal counsel in case

of any doubt or clarification in understanding the laws.

We are committed to keeping our customers satisfied by providing products and services of the desired quality at the lowest possible cost.

Total Quality Management (TQM)

TQM is a work culture which seeks continuous improvements in quality. It focuses on improving the process, uses a cross-functional approach and involves every employee. The main goal is customer satisfaction.

The company's quality management programme is headed by Mr. L.V. Keshav, Sr. Vice President - R&D, Corporate Quality and Systems. An Apex Quality Council (AQC) comprising senior management and headed by our Vice Chairman and our Managing Director has been set up to direct and monitor initiatives and progress on the quality front, companywide. A Corporate Quality team coordinates quality/ environmental initiatives and supports the AQC.

Each regional office has a core team trained in ISO 9000 and other quality requirements and is responsible for the implementation of quality systems and audit requirements. Each division and regional office has a quality coordinator for all activities, who reports to the divisional head - the Corporate Quality team on quality/environment related issues.

A Central Audit Group (CAG) has been formed with auditors from all divisions to bring out gaps that exist between procedure and practice. This group is trained not only on ISO 9000/14000 but also on auditing techniques and is responsible for quality system audits at all regional offices and units.

At selected locations, cross-functional teams have been set up to work on pilot quality improvement projects. Training programmes are held to explain the concepts and processes involved in such projects that are aimed at obtaining annual improvements in quality and annual reduction in the costs of poor quality.

ISO 9000 Quality Management Systems

Systems are vital for the proper functioning of an organisation. We are a totally ISO 9000 certified company. All operating units of the company as well as its R&D are ISO 9000:2001 certified. ISO 9000 certification of our resin manufacturing unit at Ankleshwar made us the first ion exchange resin manufacturing company in India to obtain ISO 9000; this unit was also the first in India with an FDA approved facility for the manufacture of pharmaceutical grade speciality resins. Again, our industrial chemicals facility at Patancheru was also the first in the water treatment sector to obtain ISO 9000.

The assembly centre set up at Verna, Goa for our Consumer Products Division is the first to be certified under the new (2000) version of ISO 9000 quality systems.

In order to improve overall quality too, we have set up an additional assembly centre at Hosur to assemble and test standard plants before despatch. An assembly centre was also set up at Rabale for assembly of custom built plants for large projects. This ensures the complete supplies of right quality components that match and fit correctly and also reduces erection time at site.

While focussing on business goals and activities, the company is deeply conscious of its role and responsibility in positively impacting the environment.

We felt it important to articulate our commitment to the environment, more so because our business relates closely to the environment. This policy forms an environmental framework for our activities, helping to integrate economic and environmental goals.

Companies worldwide are realising that improving environmental performance yields significant competitive advantages. We have seen how the increasing concern of our customers about the environmental impact of their activities is leading them to seek solutions that incorporate water conservation, pollution control, energy saving and reduced chemical consumption. We believe that IEI's environmental policy will help channelise our creativity and energies towards innovative solutions that enhance customer value while improving the environment. There is also much we can do within IEI on materials, energy and waste management, which will bring direct and indirect cost savings, process efficiencies and productivity gains while protecting the environment. The company's environmental management programme is headed by Mr. L.V. Keshav, Sr. Vice President - R&D, Corporate Quality and Systems.

Two of our units - Resin (Ankleshwar) and Chemical (Patancheru), have obtained ISO 14001 environmental management certification, and many of the quality improvement projects undertaken at Ankleshwar relate to water conservation, resource optimisation and waste minimisation, all of which enhance profitability while improving the environment.

IEI pioneered water treatment in India and is one of few companies in the world with a range of technologies, products and services that covers the entire spectrum of water and waste water treatment. We are, therefore, able to provide integrated solutions for total water management to every sector - household, institutional, commercial, industrial, municipal and infrastructure - urban and rural.

From total water management in which we are the leading solutions provider, we entered the entire gamut of environment management: liquid waste treatment & recycle, air pollution control, solid & hazardous waste treatment and renewable energy from waste, through our joint venture Ion Exchange Waterleau Ltd. We are, therefore, able to provide a complete portfolio of advanced environmental solutions and services spanning water, liquid & gaseous effluents, solid & hazardous waste and renewable energy, for infrastructure, industrial, municipal and household applications.

46 years of experience

We started as a subsidiary of the Permutit Company of UK in 1964. Permutit divested their holdings in 1985 and we became a wholly Indian Company. We have four and half decades of experience in the manufacture of world class ion exchange resins, starting with the well known ZeoKarb and DeAcidite brands, and our range of INDION ion exchange resins equals the best. We have 46 years of experience too, in the design and supply of water, process liquid and waste water treatment plants - packaged, pre-engineered and custom built. More than 50,000 plants have been commissioned in India and abroad, of which over 500 installations are at thermal and nuclear power plants, fertiliser factories, refineries, petrochemicals and other industries, including a number of projects on global tender basis. Our plants, ion exchange resins and water treatment chemicals are exported to S.E.Asia, Japan, Europe, Africa, the Middle East, USA and UK as well as to the neighbouring countries of Bangladesh, Nepal, Mauritius and Sri Lanka.

Wide range of technologies, single source solutions

We deal with a much wider range of technologies and products than most companies in the world. Since we provide integrated solutions, clients find it much simpler and more cost effective to approach us for single window total solutions, gaining the benefit of integrated solutions while eliminating multi-point, multi- vendor coordination.

Our range of products includes water, process liquid and waste water treatment and recycle using various physico-chemical processes for settling, clarification, filtration, disinfection; membrane and ion exchange technology; ion exchange resins, membranes, polymers and polyelectrolytes for water and non-water processes; boiler/cooling water treatment chemicals, fireside chemicals and fuel additives as well as process chemicals for sugar and paper production.We also provide solutions in solid waste management and recovery of energy from waste.

Complete Service Support

We provide comprehensive technical services from, feasibility and pilot plant studies to rehabilitation and retrofitting including on Build-Own-Operate/Transfer (BOO/T) basis, operation & maintenance services, and even supply of treated water.

We also provide comprehensive consultancy services, including water management surveys and detailed project reports. Such consultancy gives customers the freedom to subsequently approach any company capable of meeting their requirements.

Our experience of working in developing countries has given us a deeper understanding of their problems, including the lack of trained technical manpower. We offer training in plant operation and maintenance as well as in the technologies supplied.

Infrastructure

Our biggest asset is people - of our 1325 people, over 300 are highly experienced engineers and chemists, many with more than ten years' experience in water treatment technologies. We have five factories in five states, regional and branch offices in most major cities and a national network of service companies, dealers, agents and stockists.

Our overseas operations in Africa, Bangladesh, Indonesia, Malaysia, Oman, Singapore, Thailand, UAE,Canada and USA are supported by an international network of agents and stockists in Bangladesh, Indonesia, Japan, Kenya, Malaysia, Nepal, Sri Lanka, Tanzania, Uganda and Zimbabwe.

Production Facilities (Factories)

Ankleshwar, Gujarat for the manufacture of ion exchange resins. This integrated anion and cation unit is fully automated and ISO 9001 and ISO 14001certified. It has a Food and Drug Administration (FDA, India) approved facility for manufacture of pharmaceutical grade speciality resins.

Hosur, Tamil Nadu for assembling packaged and pre-egineered plants and for water quality monitoring instruments is ISO 9001: 2000 certified.

Patancheru, Andhra Pradesh for the manufacture of cooling and boiler water treatment/firesidechemicals, process chemicals for paper and sugar manufacture - ISO 9001: 2000 and ISO 14001 certification.

Verna, Goa

for the assembly

of water purification/conditioning products for the household sector,

ISO 9001: 2000 certified.

Rabale, Maharashtra

for assembly and

testing of custom-built plants for exports, before shipment

ISO 9001: 2000 certification.

International Associations

We have joint ventures, licensing and representative agreements with some of the best known specialist water treatment companies in Europe, UK and Japan through which we have acquired state-of-the-art technologies.

Licensing Agreements with

| Elf Antar SA, France | Oil Separators, Coalescers and Drum Skimmers |

| Butler Manufacturing Services (BMS), Ireland | Packaged Sewage Treatment Plants |

| Nordic Water Products, Sweden | Continuous Sand Filters |

| Eutech Instruments, Singapore | Water Quality Monitoring Instruments |

| Toray, Japan | Membranes |

Representative Agreements with

| Triogen, UK | UV Sterilisers |

| Ozonia, Switzerland | Ozonators |

Joint Venture

| With Waterleau Group

(Belgium) provides single point responsibility for total environmental

solutions catering to industrial and municipal needs - liquid & gaseous effluents, bio-solids and solid waste treatment, air pollution control and recovery of energy from waste. |

R & D

At our centres for Engineering R&D at Rabale, Maharashtra and for Chemical R&D at Patancheru, Andhra Pradesh,recognised by the Department of Science & Technology Government of India, scientists work on developing new products, upgrading existing ones and indigenising technologies obtained through our foreign collaborations.

Joint Venture/Group/Associate Companies

Joint Ventures

Ion Exchange Waterleau Ltd. - our joint venture with Waterleau, Belgium has its corporate office at Vashi, Navi Mumbai; the company offers a complete portfolio of advanced environmental solutions & services - water, waste, air & renewable energy.

Group Companies

Ion Exchange Enviro Farms Ltd. - Our diversification into organic horticulture through this subsidiary is a natural extension of our activities and provides synergistic benefit. Like our core business, it shares our vision of a better world.

Ion Exchange Asia Pacific Pte. Ltd. - a subsidiary company established in Singapore to service the Pan Asean region for total water management.

IEI Environmental Management (M) Sdn. Bhd. - facilitates operations in Malaysia

Ion Exchange Environment Management (BD) Ltd. - facilitates operations in Bangladesh

Ion Exchange Infrastucture Ltd. - this subsidiary provides design, engineering and construction services with focus on turnkey projects for municipal and industrial infrastructure development.

Ion Exchange LLC, USA - subsidiary company having offices at Fremont, California and Ontario, Canada. It looks after distribution & sales in the North American market of our ion exchange resins for water and speciality applications, and water treatment equipment.

Ion Exchange & Company LLC - headquartered in Muscat, Sultanate of Oman, facilitates operations in the Middle East markets

Ion Exchange Ltd., UAE - our GCC operations, headquartered in Hamriya Free Zone, Sharjah, UAE caters to the Middle East markets & Africa offering total environmental solutions to industry as well as ZeroB water purification processes for homes.

Associate Companies

Ion Exchange Services Ltd. - is headquartered at Bangalore,with a countrywide service network, the largest in water treatment industry in Asia. It provides complete technical and value added services for water, waste water and other utilities through a committed and experienced team of over 1500 service and plant management personnel.

Astha Technical Services Pvt. Ltd. - provides detailed engineering services to reputed engineering companies & EPC contractors through team of highly experienced engineers in various disciplines.

Global Composites and Structurals Ltd. - at its fabrication facility at Wada, Maharashtra, it manufactures FRP- FW (Filament Winding) & FRP - HLP (Hands Lay Up) products, industrial electrical units and fabrication of steel equipment/structures.

To know more about our organisation, you could visit our websites:

You can also visit ‘The Green Life’ blog – a recently launched extension of our environment consciousness aimed to be a medium that spreads environment responsibility.

From small beginnings, IEI has come a long way. Our growth has been accompanied by continuous change introduced to provide departments with autonomy and people with opportunities for career growth, as well as to ensure smaller product lines are not neglected but realise their potential.

1930s - The Antecedents

Our beginnings go back 70 years to the time when The Permutit Co. of UK appointed J. Stone & Co., a Kolkata based British company, well known railway engineers, as their agent in India. The main business was from the treatment of loco feed water for the Indian Railways. Although the railway business did well for some time, with 40 automatic softeners installed, the bottom fell out of this market for Permutit when, after World War II, the Railways decided to go in for internal chemical treatment, doing it themselves. Subsequently, Permutit sold softeners to textile mills and to the first of India's major fertiliser factories of Sindri. Organisational problems led to a dwindling of sales and Permutit decided to make one last attempt at reviving their business before shutting shop in India. At this time, Mr. G. S. Ranganathan (our Chairman) was offered the position of Resident Engineer in India. After training six months with Permutit in London, he started work in 1953 at J. Stone's head office in Kolkata, with a staff of two commissioning engineers and a stenotypist.

1964 - The Origin

With luck, perseverance,

the dedicated work of staff and the help of many friends and well wishers,

sales increased and in 1964, Permutit accepted Mr. Ranganathan's recommendation

to form a subsidiary company. Ion Exchange (India) Limited thus came into

existence. IEI was incorporated on March 6, 1964 with Permutit holding 60

per cent equity.

Thus, from the outset, we had considerable background and experience in ion

exchange technology and water treatment as we were associated with the Portals

Group of UK (who acquired Permutit in 1970) and their subsidiaries, Permutit-Boby

and Paterson Candy International, world famous in water treatment, and had

access to their expertise.

1965 - Production Commences

Backed by Permutit, IEI produced for the first time in India, an extensive range of modern ion exchange reins conforming to international standards. Concurrently, we established design capabilities to engineer and produce water and waste water treatment equipment.

… The Organisation takes shape

Our initial three main divisions were Production, Sales and Contracts. Production covered the manufacture of ion exchangers and plant assembly. Sales covered plant and spares and was additionally responsible for field services like plant erection, commissioning, servicing and trouble shooting. Contracts (consisting of draughtsmen, an inspector and purchaser) handled all purchase decisions. Resin manufacture and small size plant assembly was done at Ambernath, while all other activities were handled by the Mumbai office. Other support functions (custom clearance, warehousing and despatch, accounting etc.) were provided by various branch offices of J. Stone.

1966 - Departments start forming

By end 1965, Sales and Contracts were merged into a single division. Departments started forming within the division from 1966 and fairly sharp inter-departmental boundaries were visible by 1967. The departments were Sales, Drawing Office, Purchase, Inspection, Field Services and a Development Cell. Within the same Sales Department, small plants, ion exchangers and non-standard plants came to be handled by separate individuals or groups. The Development Cell was taken out of the Sales and Contracts Division and shifted to Ambernath, where Engineering R&D evolved out of it in 1967. Accounts became a separate department, Production continued as before and a Personnel Department took shape in the early '70s.

1968 - Networking across India

Regional offices were established in Chennai - South (1968), Delhi - North (1969), Kolkata - East (1983) and Mumbai - Western Region (1985); branches were subsequently opened in Hyderabad (1988), Bangalore (1990), Lucknow (1991), Vadodara (1992; Pune (1992), Vashi (1993) , Chandigarh (1994), Indore (2000; closed in 2008), Visakhapatnam (2007), and Bhubaneshwar (2008). In 2006, the Western Regional Office was shifted to Vashi, Navi Mumbai.

A project office at Pune was established in 1989 (closed in 1999), followed in 1993 by another in Vashi,in 1995 in Kolkata and in 1998 in Rabale & Navi Mumbai.

Production Facilities

Ankleshwar Ion Exchangers & Chemicals Ltd., a wholly owned subsidiary of IEI, set up a plant at Ankleshwar which commenced production in 1979. It was merged with IEI in 1982 as a separate division. The Standard Plants unit was set up in Hosur, Tamil Nadu and commenced production in 1982, followed a year later, by the Industrial Chemicals unit in Patancheru, Andhra Pradesh, which started production in 1983; instruments at Hosur (1989), Consumer Products at Verna, Goa (1998) and a 100% EOU at Rabale, also in 1998.

...and R& D

While R&D started soon after production began, a formal R&D Centre was established in 1973 at Ambernath. R&D Chemicals was shifted to Patancheru in 1999 and R&D Engineering was shifted to Rabale in 2002.

The '70s and '80s - An expanding product range

Throughout the late '70s and early '80s, we continued to add to our range of products, including reverse osmosis units, electro-chlorinators, and condensate polishers and effluent treatment plants. We also introduced new activities like plant upgrading under Customer Services.

In 1978, ours became the first company in India to apply reverse osmosis as a complementary process to ion exchange.

1980 onwards saw a number of technical collaborations, joint ventures, licensing agreements and marketing tie-ups with the best known specialist companies in USA, Western Europe, UK and Japan.

From 1985, as wholly owned Indian Company

In 1985, Permutit divested their holding after which, we became a wholly Indian Company. Our shares are quoted on Mumbai Stock Exchange. They are widely held with the public holding 46 per cent of equity, 18 per cent by Financial Institutions and 23 per cent by Employee Welfare Trusts, making ours one of the very few companies in India to have such a large percentage of equity in Employee Trusts.

Today, we are one of just three of four companies worldwide with such a wide and diverse range of technologies and products in water and waste water treatment, enabling us to provide total water and environment management solutions. Our in-depth understanding of the Indian & South East Asian markets and an enviable sales and service infrastructure has been built up assiduously over four and a half decades. We are highly respected as a professionally managed company, commanding leadership status in the environment management industry with a reputation for innovation and reliability.

A.1.10 TOTAL ENVIRONMENT MANAGEMENT

IEI has pioneered integrated, total water management solutions to meet the growing need for good quality water even as water scarcity and waste pollution increases .Using a wide range of technologies and an integrated approach, we deliver total solutions for industries, homes and communities, urban and rural. With the formation of our joint venture Ion Exchange Waterleau Ltd. we extended our solutions to cover the entire gamut of environment management, enabling us to provide total water & environment solutions management through the widest range of products and services internationally. We serve practically every sector - municipal, infrastructure, industrial, institutional and residential, urban and rural.

A.1.10.1 INDUSTRIAL

We provide industry with total water & environment management - from pretreatment, through process and waste water treatment, to water recycle and recovery of valuable byproducts for reuse in process; solid waste management, air pollution control and recovery of energy from waste. Our total solutions addresses environmental concerns of customers by incorporating water conservation, pollution control, energy saving and reduced chemical consumption. Contracts for supply of plant including its O&M save our customers capital expense, supervision and the hassle of maintaining facilities in-house, while letting them concentrate on their core business.

| Pre-treatment (To remove undissolved impurities) | ||

| Coagulation & Flocculation | Polyelectrolytes Chemical Dosing Systems |

|

| Clarification | Polyelectrolytes |

|

| Clariflocculators | ||

| High/Ultra High Rate Solid Contact Clarifiers | ||

| Lamella Clarifiers | ||

| Precipitators | ||

| Filtration | Multigrade Filters |

|

| Single and Dual Media Filters | ||

| Activated Carbon Filters | ||

| Continuous Sand Filters | ||

| Monovalve/Monoscour Filters | ||

| Auto Valveless Gravity Filters Ultra Filtration Systems | ||

| Process Treatment (To remove dissolved impurities) | ||

| Softeners |

Trolley mounted reverse osmosis system with pretreatment for army camps  Sea water desalination plant |

|

| Dealkalisers | ||

| Demineralisers | ||

| Reverse Osmosis | ||

| Ultra Filtration | ||

| Micron Filters | ||

| Monitoring Instruments | ||

| Ozonators | ||

| Chlorinators | ||

| Post Conditioning | ||

| Chemical Dosing

Systems |

Condensate Polishers |

|

| Deaerators | ||

| Condensate Polishing | ||

| Boiler Water Chemicals | ||

| Sidestream Filters | ||

| Cooling Water Chemicals | ||

| Waste Water Treatment | ||

| Polyelectrolytes |

Recycle of concentrated oily waste water |

|

| Oil and Grease Removal Systems | ||

| Ultra Filtration for Oily Waste Treatment | ||

| Activated Sludge Systems | ||

| Sequential Batch Reactor | ||

| Membrane Bio-Reactor | ||

| Anaerobic Processes | ||

| High Rate Solids Contact Clarifiers | ||

| Trickling Filters | ||

| Bacterial Cultures | ||

| Water Recycle | ||

| Pressure Filters |

|

|

| Continuous Sand Filters | ||

| Photochemical Oxidation | ||

| Reverse Osmosis | ||

| Disinfection | ||

| Demineralisers | ||

| Ultra Filtration | ||

| Membrane Bio-Reactor | ||

| Car Wash Recycle System | ||

| Sewage Treatment | ||

| Bar Screens |

Fluidised media reactor for sewage treatment |

|

| Aerators | ||

| Clarifiers | ||

| Multigrade Filters | ||

| Activated Carbon Filters | ||

| Packaged & Customised Sewage Treatment Plants | ||

| Fluidised Media Reactor | ||

| Membrane Bio-Reactor | Sequential Batch Reactor | |

| Reed Bed Systems | ||

| Disinfection Systems | ||

| Drinking Water Treatment | ||

| Electrochlorinators |

ZeroB Water Station |

|

| Hypocholorite Dosing | ||

| UV Sterilisers | ||

| Ultra Filtration | ||

| Reverse Osmosis | ||

| Ozonation | ||

| Disinfection | ||

| Iodinated Resin Purifiers | ||

| Fluoride Removal | ||

| Nitrate Removal | ||

| Iron Removal | ||

| Arsenic Removal | ||

| Heavy Metal Removal | ||

ZeroB

Pristine ROp |

ZeroB

Ultimate reverse osmosis (RO) purifier |

|

| Air Pollution Control | ||

| Gas

Cleaning Collision Scrubber Process |

|

|

| Bio-Scrubber

Process Oxidation |

||

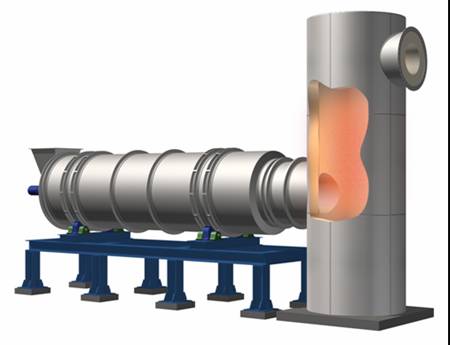

| VOC

Control Regenerative Catalytic Oxidiser |

||

| Regenerative

Thermal Oxidiser Multifluid Thermal Oxidiser |

||

| Solid Waste Management | ||

| Horizontal Disk Dryer |  Disk dryer  Dryer-granulator |

|

| Dryer-Granulator | ||

| Multifluid Thermal Oxidiser | ||

| Grate | ||

| Rotary Furnace | ||

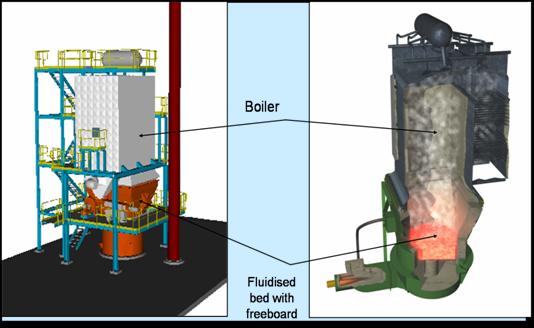

| Fluidised Bed Reactor | ||

| Renewable Energy | ||

| Anaerobic Systems |  Fluidised bed

reactor  Combustion technology |

|

| Horizontal Disk Dryer | ||

| Dryer-Granulator | ||

A.1.10.2 RESIDENTIAL

A whole range of water treatment solutions that provide assured quality of water for every domestic use - from drinking and cooking, to bathing, laundry and swimming pool, as well as sewage recycle systems that provide assurance against water shortages. Water care teams visit homes to familiarise customers with products and offer customer support while prompt and cost effective service is provided by a country wide network of service companies.

Drinking Water Purification

Catering to every consumer segment and budget is a wide range of ZeroB water purifiers that provide ultimate protection against waterborne diseases, by eliminating disease-causing micro organisms on contact. They come in a wide range of convenient devices to provide all consumer segments with safe drinking water.

Product Range

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Water Conditioners

We also offer water conditioners to handle hardness and excessive iron in water. Our systems deal with problems caused by minerals like calcium, magnesium and iron in water. These condition the water to remove impurities from it to make it safe for use.

|

|

|

|

|

|

|

Pool

Sparkler - Swimming pool filtration system

|

Sewage Treatment and Recycle

INDION

New Generation Packaged Sewage Treatment Plant

(NGPSTP) |

|

|

|

INDION

Fluidised Media Reactor (FMR) for Sewage Treatment |

|

|

|

A.1.10.3 COMMUNITIES

Increasing pollution of surface and ground water has turned these sources of water supply into a soup of contaminants including mineral salts, trace metals, organic compounds, dissolved gases and colloidal matter, particles in suspension and micro-organisms. Thus the quality of water supplied to communities, particularly for drinking, has become a paramount concern. Moreover, many communities are severely stressed because of increasing water scarcity.

Using its vast experience in total water management, Ion Exchange India offers total water solutions that

• provide safe drinking

water at an affordable cost

• treat waste water to comply with discharge regulations

• conserve fresh water while reducing pollution, through recycle

In the public health sector, our drinking water solutions are ideal for communities that receive ground or surface water supplies. We also undertake projects for waste water/sullage/sewage treatment and recycle.

Treatment

processes cover

• turbidity removal

• disinfection

• iron, fluoride, nitrate and arsenic removal

• softening

• brackish water treatment and desalination of sea water

• treatment and recycle of sewage and common industrial effluent

Technology is backed by operator training and technical services

Most rural areas in India experience severe water scarcity. The little water that people have to depend on is often unfit for use, let alone for drinking. We have sought to combine our business objectives and social responsibility through technology that can provide safe drinking water and a better quality of life to millions of people in rural areas.

In taking our technology to rural India we have adapted it to suit rural needs in terms of appropriateness, cost, operation and maintenance. Our safe water solutions address rural needs at three levels - point of use, community and infrastructure. Our approach is to combine provision of appropriate technology, training and services with community involvement for continuity, through organisations that have a long-term presence in the villages.

Our allied services

include

• Promotion of rainwater harvesting and watershed development

• Consultancy and marketing support for organic farming through

our agri-subsidiary

Disaster Management

During calamities such as cyclones, floods and earthquakes, water supplies get contaminated with suspended solids, dirt, clay and pathogenic bacteria, spreading disease and epidemics which add to the affliction of the affected communities.

Our mobile unit for drinking water uses a combination of membrane processes and ozonation to treat any type of available water, ground or surface, and make it safe for drinking. The compact, containerised unit can be truck mounted and easily & quickly transported to the affected sites. It can be operated on a diesel generator and so is not dependent on electricity availability/connections. It can treat any kind and quality of surface or high salinity ground water to produce drinking water conforming to stringent IS 10500 standards.

ZeroB Srijal and ZeroB Suraksha point-of-use drinking water purifiers, specially developed for semi-urban and rural areas, are also ideal for use during calamities outbreak. Priced so they are affordable by low income sectors, they do not require electricity, are simple to use, and require hardly any maintenance as they have no moving parts.

Date of Incorporation

6.3.1964

Annual turnover for 2009-10 ` 514 crores

Number of employees 1325

Registered capital

` 15 crores

Board of Directors

Mr. G. S. Ranganathan

- Chairman

Mr. Rajesh Sharma - Vice Chairman & Managing Director

Mr. V. N. Gupchup

Mr. A. K. Marfatia

Mr. M. R. Menon

Mr. T. M. M. Nambiar

Mr. M. P. Patni

Mr. Aankur Patni

Mr. P. Sampathkumar

Mr. Abhiram Seth

Mr. Dinesh Sharma

Mr. Shishir Tamotia

Organisation Realignment for Business Strategy

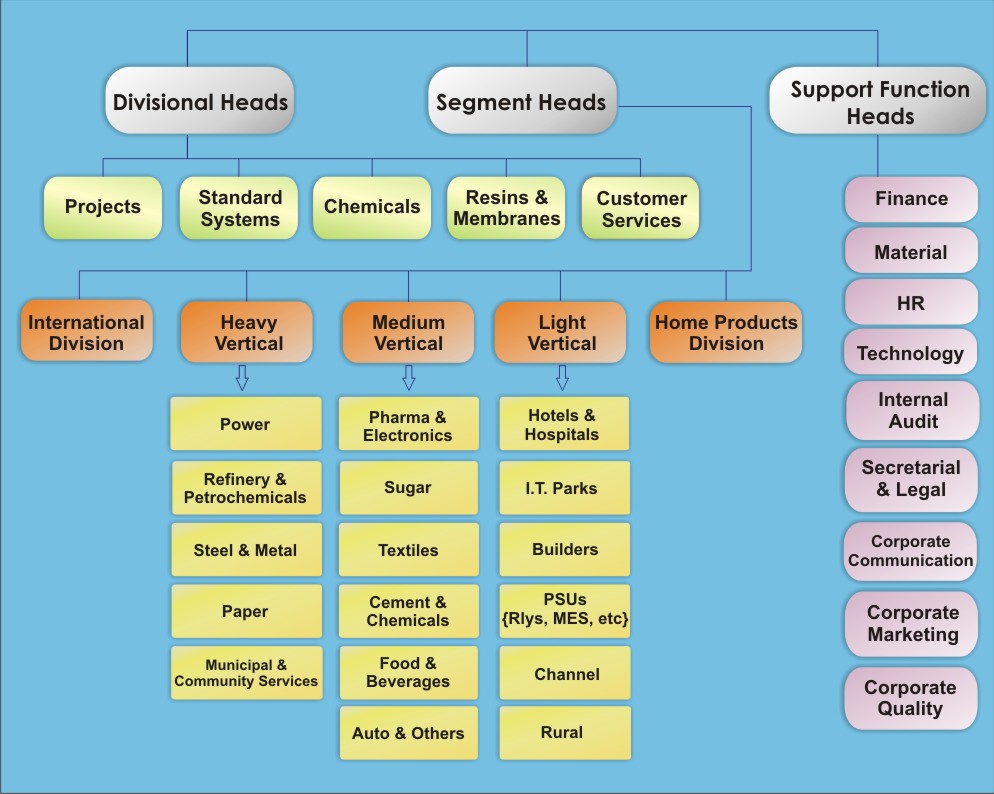

In 2008 we took up the exercise of developing a long term business strategy for the company and therefore divisions worked on aligning its divisional strategy with the overall strategy of the company. Consensus emerged regarding the need to leverage the our capability to provide Total Environment Management Solutions (TEMS) and that the divisional structure, which is more productline focused, does not lend itself to effective re-orientation towards the TEMS approach.

In order to augment our customer reach, service customers better and enhance customer satisfaction through a customer centric, one stop package of TEMS, industry specific verticals were created. This would help the verticals teams to acquire industry-specific knowledge, so that tailor-made solutions can be offered, and help in developing stronger customer relationships and one-point contact through which we would be able to provide TEMS. (Power, Steel, Sugar, Pharma, Paper and Infrastructure Verticalshad been created 2 years ago and were delivering these benefits).

Therefore, based on the business strategy, in April 2009 the organisation has been re-structured and oriented towards 3 major industry segments i.e. heavy industry, medium industry and light industry, each divided into various verticals.

Verticals are responsible for marketing, sales and profit targets of the respective vertical.

Divisions continue to be responsible for production, quality, delivery, cost control, capacity utilisation and working capital management. They are also responsible for product development and provide technical and sales support to the verticals.

Regions are responsible primarily for regional marketing share, regional profit targets and customer relationship management besides corporate marketing, and commercial and administration functions of regional office.

Corporate Marketing Group carries out market research, determines market potential for verticals and facilitates increase in market share through Key Customer Account Management.

These changes are enabling the company to exert a much greater focus on our unique offering of integrated, total solutions to customers, significantly enhance the early traction of our customer account management and better position us to meet evolving customer needs. The realignment is providing the organisation structure necessary to effectively deploy business strategy, enlarge our competitive advantage, increase our market share, grow our brands, revenues and profits and enhance our leadership position, to deliver the long term growth objectives of the company.

Recognising the importance of services, we have during the past decade built up the strongest service network.

Our services include:

• Consultancy

• Water Management Surveys

• Feasibility & Pilot Plant Studies

• Design & Engineering

• Project Management

• Inspection

• Erection & Commissioning

• Upgrading and Modernisation of Plant, including through Bulid-Own-Operate/Transfer

(BOO/T) basis

• Operation & Maintenance Contracts

• Operator Training

• Servicing

We now offer contracts for supply of plant including its O&M, thus taking total responsibility. This package is economical and convenient, saves our customers capital expense, supervision, and the hassle of maintaining facilities in-house, while letting them concentrate on their core business. We plan to even sell water, of any quality for any purpose, to meet customer requirements.

Highly experienced engineers at our Customer Services Division at Rabale provide troubleshooting and advice on optimum equipment operation, annual service contracts, essential spares and consumables. The division specialises in rehabilitation and upgrading of water treatment plants to improve quality, augment capacity, reduce chemical consumption and provide automation. It undertakes O&M contracts and projects on BOO/T basis.

Our consultancy division Total Water Management Services offers comprehensive consultancy in water and waste water management, from concept through basic and detailed engineering, to commissioning and monitoring operations. Feasibility studies include problem identification, evaluation of alternate options with cost-benefit analysis and recommendation of optimum solutions.

Our associate company Ion Exchange Services Ltd., , through its all India network and team of 1500 service engineers, services customers of plants in the medium and light sectors.

Networking... in India and worldwide

Corporate Office

• Mumbai

International Division & Local Projects

• Rabale

Customer Services & Home Water Solutions

• Vashi

Regional Offices

• Kolkata • Chennai • Delhi • Mumbai

Branches

• Bhubaneshwar • Chandigarh • Hyderabad • Lucknow

• Pune •Vadodara • Visakhapatnam • Vashi

Project Offices

• Rabale • Vashi

Production Facilities

•Patancheru, Andhra Pradesh • Verna, Goa • Ankleshwar, Gujarat

• Rabale, Maharashtra

• Hosur, Tamil Nadu

Dealers

• Ahmedabad • Ankleshwar • Amritsar, • Bangalore •

Bardhaman • Bhopal

• Bhubaneshwar • Chandigarh • Chennai • Cochin •

Coimbatore • Daman • Durgapur • Erode

• Goa • Guwahati • Hyderabad • Indore • Jaipur

• Jamshedpur • Jharkhand • Kanpur • Kolkata

• Kota • Lucknow • Ludhiana • Mumbai • Nagpur

• Navi Mumbai • New Delhi • Orissa • Pune

• Punjab • Raipur • Rajkot • Rajahmundry • Secunderabad

• Vapi • Vadodara • Visakhapatnam

Overseas Offices

•Bangkok and Rayong, Thailand •Nairobi, East Africa •Johannesburg,

South Africa •Ontario, Canada

•Dhaka, Bangladesh • Jakarta, Indonesia • Kaula Lumpur,

Malyasia • Muscat, Oman • Sharjah, UAE

• Fremont, USA

International Agents

• Bahrain• Qatar • Saudi Arabia • Nigeria

Over the past 46 years, IEI's operations have grown from ` 24 lakhs(1965) to ` 514 crores (2009-10).

A public limited company, Ion Exchange India was formed in 1964 as a subsidiary of Permutit of UK, who divested their equity holding in 1983. We are now a wholly Indian company with shares quoted on the Mumbai Stock Exchange and an unbroken record of paying dividends from the second year of incorporation except in the year 2000-01. The company has made 3 rights issues, 1 public issue and 4 bonus issues of shares and paid up capital on 31.3.2010 was `12.73crores.

Participation for shareholders has always been rewarding with an impressive track record of dividend payout.

Income of the company for the financial year 2009-10 was ` 514 crores (Sales is inclusive of excise) with profit before tax of ` 10.21crores. After taxation the net profit stood at ` 6.61crores.The company had declared a dividend of 15% for the year 2009-10.

10 Years At A Glance (Rupees. in Lakhs)

Year |

2009-10 |

2008-09 |

2007-08

|

2006-07

|

2005-06

|

2004-05

|

2003-04 |

2002-03 |

2001-02

|

2000-01

|

Income |

51840 |

45474 |

50979 |

44486 |

32457 |

26105 |

21532 |

19457 |

19005 |

17108 |

Profit/(loss)

Before Tax |

1021 |

373 |

1567 |

1033 |

703 |

501 |

265 |

296 |

580 |

(462) |

Tax (Excluding

Fringe Benefit Tax) |

360 |

117 |

335 |

337 |

74 |

21 |

69 |

116 |

113 |

6 |

Fringe Benefit

tax |

- |

112 |

167 |

98 |

124 |

- |

- |

- |

- |

- |

Profit/(Loss) After Tax |

661 |

144 |

1065 |

598 |

505 |

480 |

196 |

180 |

467 |

(468) |

Dividend# |

223 |

149 |

307 |

211 |

131 |

127 |

124 |

122 |

107 |

- |

Dividend(%) |

15% |

10% |

20% |

15% |

10% |

10% |

10% |

10% |

10% |

- |

Retained Earnings |

438 |

(5) |

758 |

387 |

374 |

353 |

72 |

58 |

360 |

(468) |

Fixed Assets** |

5873 |

6407 |

6502 |

4925 |

4234 |

4208 |

4454 |

4640 |

4880 |

5025 |

Investments |

2544 |

1024 |

917 |

642 |

416 |

308 |

301 |

285 |

284 |

458 |

Net Current Assets*** |

10091 |

13305 |

12735 |

11506 |

13526 |

13316 |

12221 |

12676 |

10793 |

10910 |

Miscellaneous Expenditure |

- |

- |

- |

- |

20 |

47 |

76 |

111 |

95 |

212 |

Share Capital |

1273 |

1269 |

1266 |

1199 |

1141 |

1113 |

1099 |

1082 |

1075 |

1075 |

Reserves & Surplus** |

12166 |

11581 |

11409 |

10199 |

9582 |

9168 |

8769 |

8679 |

8607 |

8082 |

Borrowings |

5069 |

7886 |

7480 |

5675 |

7473 |

7598 |

7184 |

7951 |

6370 |

7449 |

* Sales is inclusive of excise.

** Figures excluding

fixed assets revaluation. *** Includes Net Deferred Tax Assets / Liabilities # Includes tax on dividend,if any A.2. OUR

PROFESSIONAL APPROACH A.2.1

IEI SHAREHOLDING EMPLOYEE WELFARE TRUSTS People, a priority…After

Permutit divested its holding in 1985, IEI directed apart of their holding

towards setting up Employee Welfare Trusts to enable employees to share the

Company's prosperity. IEI has, from its

inception, followed progressive personnel policies. The Company strongly believes

that its greatest asset is its human resource and has therefore encouraged

employee participation and involvement in its activities. In 1985, Permutit

decided to divest their 39 per cent equity holding. Inspired by the Scott

Bader Commonwealth Limited Trust, UK, IEI's management proposed that a part

of the shareholding be offered to Trusts which would be formed for employee

welfare. IEI instituted the IEI Shareholding Employee Welfare Trusts and provided

the funds for the purchase of its shares by these trusts, through which employees

now hold about 23 per cent equity in the Company.

Our technological capability is backed by sustained in-house Research and Development. Our R&D which has developed more than 50 products, with 30 patents to its credit, has undoubtedly helped us to establish a competitive edge in our business.

IEI has been engaged in R&D almost from its inception. With long term developments in view, independent R&D facilities were established in a separate building at Ambernath in 1973 and our R&D Centre has been recognised by the Department of Science and Technology, Government of India since 1976. The Chemical R&D facilities shifted to Patancheru in 1999, while Engineering R&D shifted to Rabale in2002. Our R&D is 9000:2001 certified.

Our R&D is involved in all technologies which we apply today and those which we plan to use in the future. It provides improvements in current technologies, adapts processes and systems to meet special needs and undertakes development work on resins, chemicals and equipment. While our many excellent collaborations with internationally known companies have considerably helped us, R&D remains our largest investment in technological development.

R&D activities undertaken by the scientists include development of:

Apart from various kinds of ion exchange resins for water treatment, R&D has developed specialty resins - catalytic, pharma and nuclear grade and chelating type, enabling IEI to enter into new areas of application. For the water treatment chemicals and sugar chemicals businesses, basic raw materials & formulations, and sugar chemicals respectively, were developed. In the consumer range, one of the most popular products developed is ZeroB, which helped launch us in the consumer market.

Continuous emphasis is placed on import substitution, technology upgradation and adaptation and product development. This has helped the Company to establish market leadership, expand its product range and open up new markets.

Technology Group

The Technology Group keeps abreast of treatment technologies developed worldwide, including those acquired by IEI. It co-ordinates the testing of new products developed by R&D and gives vital feedback regarding subsequent development. Its engineers also conduct water management surveys and prepare action-oriented feasibility studies and reports. The unit also aids in troubleshooting, disseminates technical information and participates in technical seminars and conferences. With their specialised knowledge of treatment processes, this team not only helps in new product development, but also improves existing ranges through value engineering.

We believe that people are our greatest asset and that the success of a company depends on the excellence of all who work for it. Learning organisations are the organisations of the future. To this end we have made Human Resource Development a focus area, and attach as much importance to training as to technology.

Rather than look at the need for training in isolation, a linkage is established to the short and long term business goals as well as training needs identified through the annual appraisal system. Thus, at the beginning of the year, divisions identify the specific training requirements in order to help achieve their business goals of each division. The training needs are classified into functional, behavioural, technical and quality systems and based on these needs, a detailed training calendar is prepared at the beginning of the financial year. Training programmes are organised in-house with internal or external faculty. Employees are also deputed to relevant external training programmes wherever required.

To provide a permanent setting which will be a powerful aid in maintaining our excellence, we have set up residential training centres at Devlali and Panchgani.

A.2.4 PERFORMANCE APPRAISAL SYSTEM

Human resource is a company's key asset, more so in today's competitive and challenging business environment. The appraisal process is important because it helps identify the strengths of an employee, the potential for development and career growth, areas of improvement and the training required. It also serves as a tool for long term manpower planning and development.

Since appraisals are intended to review performance against set objectives, reward outstanding achievements, provide counseling for unsatisfactory performance and guidance for growth, they are conducted on a regular basis to derive maximum benefit. Confirmed employees are appraised annually, trainees every six months and probationers once in three months. The appraisal is conducted by the immediate superior on prescribed forms that differ for different grades.

The appraisal process is designed to ensure the participation of both appraiser and appraisee in identifying key result areas (KRAs), reviewing performance, identifying areas for the appraiser's development and sharing formation and feedback for employee and organisational improvement.

The process follows the following format:

The performance appraisal form:

Is designed in a simple format, requiring less written input; however, it requires the superior and the employee to spend time setting KRAs at the beginning of the year and reviewing them quarterly. It therefore provides opportunity for interaction, guidance and counseling on a regular basis.

A.2.5 COMPUTERISATION & INFORMATION SYSTEMS

Good communication and information systems are essential for an organisation. Priority is therefore being given to defining information needs, setting up appropriate information systems, and increasing the pace of computerisation to derive the full benefits of Information Technology.

To provide the best technology system and services, as information technology is vital for an efficient and profitable Ion Exchange India.

The current setup marks a paradigm shift from physical data entry at a centralized point to the widespread use of Information Technology and the introduction of on-line systems at each unit/location. Over ten of our locations have Local Area Networks (LANs) with a combined strength of15 servers running on various operating systems like Linux & Windows.

The future plan is to connect all locations using leased connectivity/wireless connectivity. All applications are intended to run on centrally managed database. New business intelligent and data warehousing products also will be added.

ERP package, developed in-house, is being implemented all over the company on Oracle and Windows 2000 platforms. This ERP package consists of the following modules:

We have the following packages for our Home Water Solutions Division:

The following packages are running on our internal website http://www.ionxchng.com/www.ionexchange.in

The packages that have been implemented across all divisions & locations i.e. Engineering, Resin, Chemicals, Standard Plants, Consumer Products, are as follows:

Computer aided design and drafting techniques were introduced in 1984. Engineering drawings, installation plans, pipe work designs, valve scheduling tank and vessel designs are all developed using customised software. We have introduced Auto plant 3D software to standardize the drawing and engineering designs.

Project monitoring has been computerised using Primavera and Microsoft Project '98softwares. There a lisation of the true benefits of integrated and on-line systems have led to a demand for increasing the number of such systems. Besides, systems are regularly reviewed for upgrading and new programmes are developed to meet the changing needs.

Communication with users is also ongoing for feedback on problems encountered and suggestions on improvement.

A.2.6 CUSTOMER RELATIONSHIP MANAGEMENT

Customer satisfaction has always been a core value of IEI. In today's competitive market place, managing & retaining the customer is critical to a company's profitability and growth. Look at these facts on customer acquisition, satisfaction and retention.

A.2.6.1 CUSTOMER ACCOUNT MANAGEMENT

Customer Account Management (CAM) has hence become a "must-do" initiative for companies to grow sales & profits. Corporate Marketing Groups (CMG) through the regional offices and HO is responsible for implementing and facilitating this important programme. Under CAM, sales and marketing personnel are responsible for managing a customer "accounts" i.e. managing all these customers' needs relating to all IEI products and services. He/she will generate business opportunities / enquiries, and in turn will be supported by the respective verticals/divisions for appropriate and speedy response.

The following activities are carried out under this programme and form a major KRA: To establish total potential for all IEI products for the identified customers

Formats for capturing and reporting information related to the CAM programme have been prepared. Regional heads facilitate the implementation and coordination of the programme to ensure the above objectives are met. It is reviewed during the monthly regional review meets, and regional heads report on progress to CMG, HO every month.

The formats and data are now on-line for access, update and reporting. The CAM program will be a significant part of the web enabled CRM, which is under development.

The implementation of CAM enables us to achieve the objectives of building a long lasting business relationships with our customers, providing an opportunity to be personally responsible for meeting all the customer's needs, and thereby realising higher sales, profitability and prosperity for our company.

A.2.6.2 CUSTOMER SERVICE DESKS

It's not enough to respond promptly and effectively to customer queries, problems or complaints. To reap real benefit from customer concerns requires a system to collect, analyse and interpret the complaints and to use the data generated for continuous improvement.

To this end, customer relation desks have been set up across the company, at our corporate office, sales offices and execution centres. Customer relation officers (CROs) have been identified to manage these desks, to serve as points of contact that receive and respond to customer calls with regard to

Through a web-enabled programme the CROs network among themselves and with respective departments in the sales/service, execution centres to ensure that customers receive a quick and quality response and they follow up to ensure that queries and problems are attended to within the timeframe committed by the respective departments. They also capture data for central analysis and use by the company to improve its products, services and processes.

The CROs thus perform an important role in helping retain existing customers, converting dissatisfied customers in to satisfied ones, and also obtaining new customers for the company. They become vehicles for building customer rapport and enhancing company image, providing a single point contact for customers.

Currently we have 35 CRO desks companywide.

ZeroB helpdesk

The HWS division has launched a ZeroB all-India centralised 24 x 7 customer care number 180030181818. This service is functional 365 days in a year.

In today's age of information explosion, having the right information at the right time is crucial to quick and good decision-making. And a well stocked, efficiently managed library therefore plays an important role.

Our library at Rabale witnesses to the importance our management places on this by stocking a vast and valuable collection of information sources Books- Over 4700, covering subjects ranging from water treatment technologies, environmental science and technology, chemistry, engineering, management, law, photography, history and psychology to literature. Also available, is an impressive range of encyclopedias, manuals, directories, dictionaries, data sheets and maps.

Patents- European, Australian, US, Indian and other patents relating to water and wastewater treatment, resin/polymer preparation and applications, corrosion and scale inhibition in boiler and cooling water.

Standards- In stocks are Indian, British as well as WHO, ASTM, ASME and NACE standards.

Periodicals-

The library subscribes to foreign and Indian periodicals, spanning business,

engineering, water treatment and environmental science.

Technical Papers - Over 3,000 technical articles and conference papers relating

to water treatment processes, boiler and cooling water treatment, resin properties

and preparations, condensate polishing and membrane technology.

Trade Literature - Product literature catalogues of about 900 international and Indian companies.

Apart from the above, our library also stocks Technical standards & codes, Client Certificates. Operation and Maintenance Manuals, Presentations of various products and technologies sold by IEI, Design guidelines, Case studies, Proceedings, Articles/Papers, Project reports, Know How of all products

To make this wide collection of reading material readily available, a range of services are provided by the library, overseen by a Documentation Executive, based at Rabale.

A beginning towards the goal of introducing knowledge management in IEI has been made by hosting library data on the web. After logging onto our internal website http://www.ionxchng.com/, go to Utilities under which you will find Library. There you will find information on the books and documents available at our Rabale and HO libraries. A search facility enables search by title, author and key word. You can e-mail ieilib@ionexchange.co.in with your request. (Later, a facility is planned on the site itself which will enable on-line requests for books, documents and material from the library.)

Borrowing

All available literature is issued, unless

meant solely for reference. Outstation branches and offices are given books

on a permanent loan basis. A list of books, papers and magazines are kept

at each location, with a monthly notice board update on new arrivals.

Selective

Dissemination

To save the time of library users, technical

periodicals are constantly scanned for useful information, which is summarised

and circulated to all locations, every month. Non-technical periodicals are

circulated to those at our Mumbai offices who put themselves on the circulation

list. Photocopies of the contents' pages of periodicals are also circulated

for employees to indicate the articles they wish to have a copy of.

Ready

Reference

Information queries are attended to daily.

Reference sources for different topics are cited and if required, the information

is photocopied and sent.

Electronic

Data Retrieval System

A software information and retrieval system

is used for easy retrieval according to title, publisher, subject or classification,

product or company.

Mini-Library

at Head Office

We have a well stocked library at HO too, from

which employees can borrow books.