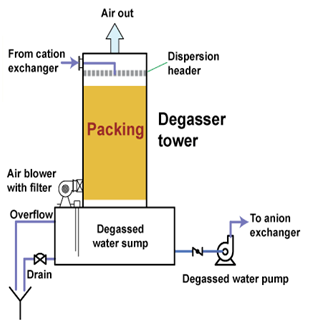

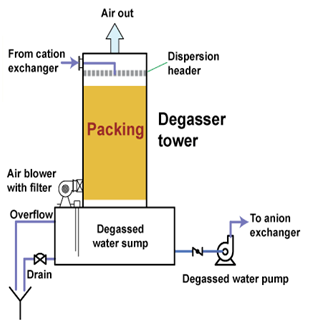

A degasser or degasifier is often used to remove dissolved carbon dioxide after cation exchange column. Degasser is an integral part of any demineralisation plant, where it is generally placed between cation and anion exchange units. It removes carbon dioxide, which is generated by dissociation of carbonic acid at cation outlet water. Degasser tower is made from either FRP or mild steel lined with rubber. Low air pressure is generated at the bottom of the tower that drives out carbon dioxide and degasser water is collected in a sump beneath the tower.

A "CO2 degasser" (degasifier) is a relatively simple water treatment device. Incoming water is sprayed into a tower filled with packing material. The drops of water that flow down through the tower strike the packing material and form a thin film on the packing material surface, encouraging the release of excess carbon dioxide. A centrifugal fan creates an updraft of air through the tower to carry away the released carbon dioxide gas. The carbon dioxide gas exits through a vent at the top of the unit.

To be effective, the degasifier must be placed after the cation exchange column. Before cation exchange, the water contains bicarbonate. After the process, the cations in water (Ca++, Mg++ and Na+ principally) are converted to H+ ions, which combine with the HCO3 bicarbonate anions to produce carbonic acid.

A "CO2 degasser" (degasifier) is a relatively simple water treatment device. Incoming water is sprayed into a tower filled with packing material. The drops of water that flow down through the tower strike the packing material and form a thin film on the packing material surface, encouraging the release of excess carbon dioxide. A centrifugal fan creates an updraft of air through the tower to carry away the released carbon dioxide gas. The carbon dioxide gas exits through a vent at the top of the unit.

To be effective, the degasifier must be placed after the cation exchange column. Before cation exchange, the water contains bicarbonate. After the process, the cations in water (Ca++, Mg++ and Na+ principally) are converted to H+ ions, which combine with the HCO3 bicarbonate anions to produce carbonic acid.

Degasser systems are available in ASME and IEI Good Engineering Practices

Degasser systems are available for flow rates of 7.5 m³/h to120 m³/h. We can design for bigger capacities based on client's requirement.

Applications:

To remove CO2 after cation exchange unit.

To reduce alkaline/anion load on SBA.

A "CO2 degasser" (degasifier) is a relatively simple water treatment device. Incoming water is sprayed into a tower filled with packing material. The drops of water that flow down through the tower strike the packing material and form a thin film on the packing material surface, encouraging the release of excess carbon dioxide. A centrifugal fan creates an updraft of air through the tower to carry away the released carbon dioxide gas. The carbon dioxide gas exits through a vent at the top of the unit.

To be effective, the degasifier must be placed after the cation exchange column. Before cation exchange, the water contains bicarbonate. After the process, the cations in water (Ca++, Mg++ and Na+ principally) are converted to H+ ions, which combine with the HCO3 bicarbonate anions to produce carbonic acid.

A "CO2 degasser" (degasifier) is a relatively simple water treatment device. Incoming water is sprayed into a tower filled with packing material. The drops of water that flow down through the tower strike the packing material and form a thin film on the packing material surface, encouraging the release of excess carbon dioxide. A centrifugal fan creates an updraft of air through the tower to carry away the released carbon dioxide gas. The carbon dioxide gas exits through a vent at the top of the unit.

To be effective, the degasifier must be placed after the cation exchange column. Before cation exchange, the water contains bicarbonate. After the process, the cations in water (Ca++, Mg++ and Na+ principally) are converted to H+ ions, which combine with the HCO3 bicarbonate anions to produce carbonic acid.